| Version 4 (modified by edison, 14 years ago) (diff) |

|---|

BarrettHand BH8-262 Troubleshooting

Most of the symptoms repeated in this section were generated by Barrett's own lab Hands which are assigned to destructive testing over millions of cycles.

Symptom: The Hand behaves erratically. It disobeys some commands while obeying others.

Possible Solution:

- Reload the Firmware. If the Hand has been idle for more than a day or two, especially in humid conditions, the SuperCap can lose enough charge that the volatile RAM becomes borderline unstable. There is never a problem if the SuperCap loses all of its charge because the Hand simply prompts user to download fresh firmware next time it is powered up. This symptom is most common in Hands that are used infrequently.

Symptom: The host computer will not communicate with the BarrettHand™.

Possible Solution:

- Verify all connections are secure to the Power Supply, BarrettHand™, and computer.

- Check that the serial cable is a straight-through extension cable.

- Verify the Power Supply is turned on.

- Firmware may no longer be valid. Try downloading the firmware.

- Host computer baud rate and BarrettHand™ baud rate may be set to different rates. Close the BarrettHand Control GUI and reset the BarrettHand™, by cycling power on the BarrettHand Power Supply. Restart the BarrettHand Control GUI and try initializing again.

- The communications port selected is being used by another program. Close all other programs that use the selected communications port. Reset the BarrettHand™ and restart the BarrettHand Control GUI.

- If the problem persists, contact Barrett Technology.

Symptom: Initial strain gage values do not fall within specified range.

Possible Solution:

- The strain gage balancing potentiometer needs to be readjusted.

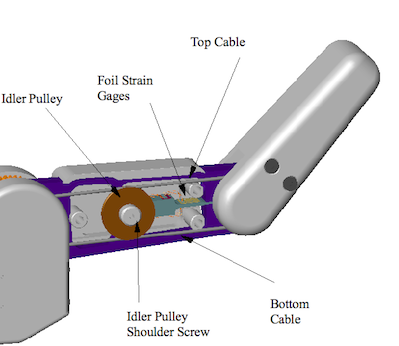

- Verify the cable is riding across both the top and the bottom of the idler pulley, as shown in Figure 25.

- If the problem persists, contact Barrett Technology.

Symptom: The strain gage values do not follow the expected strain gage curves, shown in Figure 35, while grasping.

Possible Solution:

- The finger cable pretension is not adjusted properly. Set the finger cable pretension properly.

- The strain gage balancing potentiometer needs to be readjusted.

- Verify the cable is riding properly on the idler pulley, as shown in Figure 25.

- Verify idler pulley rotates freely on the shoulder screw. The shoulder screw should not be tightened against the idler pulley. If so, loosen shoulder screw, shown in Figure 25, so the idler pulley will move with cable motion.

- If the problem persists, contact Barrett Technology.

Symptom: Only the fingertip closes when the entire finger should close (Premature Breakaway).

Possible Solution:

- Verify there is no object blocking the inner link from moving.

- The finger was not opened completely. Restore that fingers OT, IVEL, IOFF, and IHIT to their default values. Initialize the finger having the problem. The finger should now close properly.

- If the problem persists, contact Barrett Technology.

Symptom: Finger sticks fully closed.

Possible Solution:

- Verify there are no objects or other fingers blocking the finger from opening completely.

- The open velocity is too slow. Try increasing the open velocity to greater than or equal to 40 and opening the finger.

- Verify that the strain gage value SG is less than HSG (High Strain Gage Limit; alias is MSG).

- If the strain gages are not installed set HSG to 256 for the BH8-262.

- The finger cable pretension is too high. Set the finger cable pretension properly.

- Set the open velocity greater than or equal to 40 and then initialize the finger.

- Reload firmware.

- If the problem persists, contact Barrett Technology.

Symptom: Finger sticks open.

Possible Solution:

- Verify there are no objects or other fingers blocking the finger from closing.

- The close velocity is set too low. Try increasing the close velocity to greater than or equal to 40 and closing the finger.

- Set the close velocity to greater than or equal to 40 and then initialize the finger.

- Reload firmware.

- If the problem persists, contact Barrett Technology.

Symptom: Finger moves in opposite direction of commanded motion.

Possible Solution:

- Reload firmware.

- There is an encoder feedback problem. Reinitializing the finger should solve the immediate problem. If this recurs, contact Barrett Technology for servicing.

Symptom: The TorqueSwitch™ does not breakaway properly, prohibiting the fingertip from completing a form grasp around an object.

Possible Solution:

- The close velocity is too slow. Increase the close velocity greater than or equal to 40.

- Reinitialize the finger; this may reset the TorqueSwitch™.

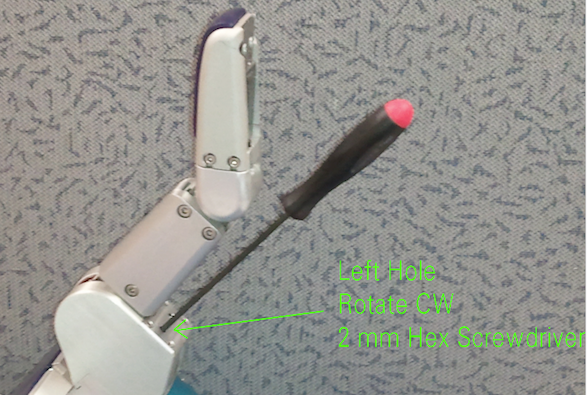

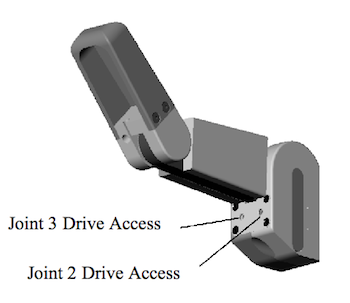

- If the BarrettHand™ has been inactive for an extended period or if the finger has been slammed open against its stop with a high velocity setting, the TorqueSwitch™ may need to be manually activated. Insert a 2-mm hex wrench into the left Drive Access hole, as shown in Figure 27. Rotate counterclockwise to open the finger fully. Next, press very hard against the inner link to constrain it from moving while not constraining the outer link, as the person's thumb is doing in Figure 26, while torqueing the hex wrench clockwise. Increase torque until the fingertip breaks free, so that it can be rotated easily while the inner link remains stationary. Remove the 2-mm hex wrench and reinitialize the finger.

- If the problem persists, contact Barrett Technology.

Symptom: Using the GTO or GTC command to open or close the fingers results in the fingers moving at slightly different velocities. This does not happen with GO and GC commands.

Possible Solution:

- Verify that the finger velocity and filter properties are the same (MCV, MOV, FPG, FDZ, FIP, SAMPLE, ACCEL).

- Unlike GO and GC commands in which each finger is position controlled to follow a predefined trapezoidal trajectory that keeps the fingers moving precisely, GTO and GTC commands apply pure proportional velocity control. Each finger has slightly different friction due to manufacturing tolerances, resulting in different actual velocities for the same commanded velocity. Lubricating the high friction fingers will help reduce the friction and increase the velocity. Alternatively, the commanded gains or commanded velocities from nominal allows you to compensate.

- If the problem persists, contact Barrett Technology.

Symptom: Fingers will not close completely.

Possible Solution:

- Adjust close target CT so that it is either at or just beyond the actual palm surface.

- Verify that the outer link has not broken away prematurely.

- Verify proper finger angles when the fingers are removed and replaced during lubrication maintenance. An error here can cause the outer finger link to reach its joint stop prematurely, even without breakaway, before either CT or the inner finger-link joint limit is reached. Verify finger angle is correct by disconnecting and reattaching fingers. Readjust if necessary.

- Verify there are no objects or other fingers blocking the finger from closing completely.

- Verify the MSG (Maximum Strain Gage) property is greater than the strain gage value (SG). If the strain gages are not installed, set MSG to 256.

- If the problem persists, contact Barrett Technology.

Symptom: The spread motion has excessive friction.

Possible Solution:

- Lubricate the spread motor gears.

- If the palm screws have been reinstalled, verify all screws are tightened with the same amount of torque. Excessive torque may cause spread friction.

- If the problem persists, contact Barrett Technology.

Symptom: The threaded locking ring does not fit on the threaded base of the BarrettHand™.

Possible Solution:

- The threaded locking ring has been damaged or is warped. Contact Barrett Technology for a replacement part.

- The threads on the base of the BarrettHand™ have been damaged. Contact Barrett Technology for service.

Symptom: The fingertip flops over backwards after a severe impact against a finger tip.

Possible Solution:

- The finger cable is broken. Verify this by removing the Shroud Cover, see Figure 23, and inspecting the cable. The cable should be intact and not broken. If the cable is broken, contact Barrett Technology.

Symptom: The fingertip has excessive backlash.

Possible Solution:

- The pretension in the cable is too low. Set the finger cable pretension properly. If the problem persists, contact Barrett Technology.

- The finger cable is broken. Verify this by removing the Shroud Cover, see Figure 23, and inspecting the cable. The cable should be intact and not broken. If the cable is broken, contact Barrett Technology.

Symptom: The fingertip has driven itself open beyond the normal full-open position and perhaps is hyperextended, but it is not loose.

Possible Solution:

- This can only happen if the spur-gear teeth are not properly engaged when the finger is reinstalled after being removed for lubrication. Verify that the finger is seated completely and square where it attaches to the palm. Verify also that the finger screw is in place and is not loose. Reset the fingertip angle and reseat the finger carefully and verify that it is seated completely and square. Test.

- If problem persists, Hand must be serviced.

Symptom: The spread fingers F1 and F2 are at different angles around the palm.

Possible Solution:

- An internal spread gear is damaged and will need to be replaced. Contact Barrett Technology.