| Version 5 (modified by bz, 10 years ago) (diff) |

|---|

BH8-282 System Components

In the Box

- BarrettHand Shipping Case

- BarrettHand BH8-282 (B4756)

- Threaded Aluminum Ring for base (B2211)

- Universal Power Supply - 48V (B4062)

- BarrettHand BH8-282 Maintenance Kit

- Acrylic finger angle fixture (B3729)

- Grease (Mobil 1) in syringe

- Small packet of Threadlock

- Tweezers

- Dental Tool

- Hex Wrench Kit

- 2mm Hex Driver, Wiha brand

- Phillips Head Screwdriver, Wiha brand, size PH1

- Flathead Screwdriver, Wiha brand, size 2

- Torque Wrench (B3436)

- Metal Stand (B3978 <-- Same part #?)

- Sheet metal Adapter Mount (B1402)

- USB-to-CAN Converter (B5382)

- USB-to-Serial Converter (B5397)

- USB Flash Drive (B3977)

- BarrettHand External Cable (B5442)

- AC Power Cable

- Serial Cable

- Barrett Technology DVD

- Business Envelope

- Quick-start Sheet

Additional Information

The Hand

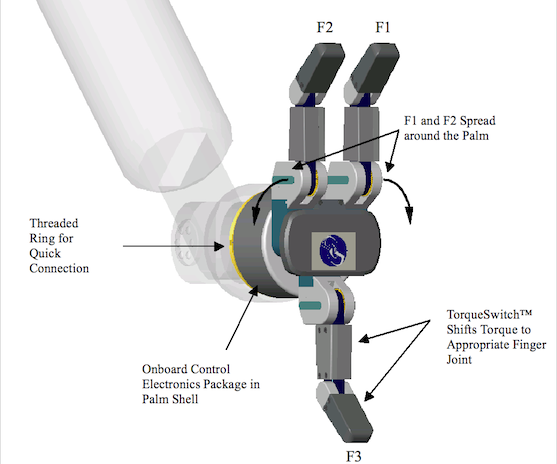

The BarrettHand™, shown in Figure 1, has three fingers labeled F1, F2 and F3. Two of the fingers, F1 & F2, rotate synchronously and symmetrically about the base joint. The “spread” motion around the palm allows “on-the-fly” grasp reconfiguration to adapt to varying target object sizes, shapes, and orientations.

Aside from the spread motion, each of the three fingers on the BarrettHand™ feature two joints driven by a single DC brushless servo motor. The joints of each finger are coupled through Barrett’s patented TorqueSwitch™, which automatically switches motor torque to the appropriate finger joint when closing on a target object. Using the fingers together allows the BarrettHand™ to "grasp" a wide variety of objects securely. The TorqueSwitch™ combined with the spread function, makes object grasping nearly target-independent.

The BarrettHand™, shown in Figure 1, is equipped with a threaded base for compact and secure mounting. The threaded base is fully compatible with the WAM Arm. And, with the arm adapter, it can be mounted on virtually any robot with a standard ISO tool plate, for easy installation and maintenance.

Power Supply

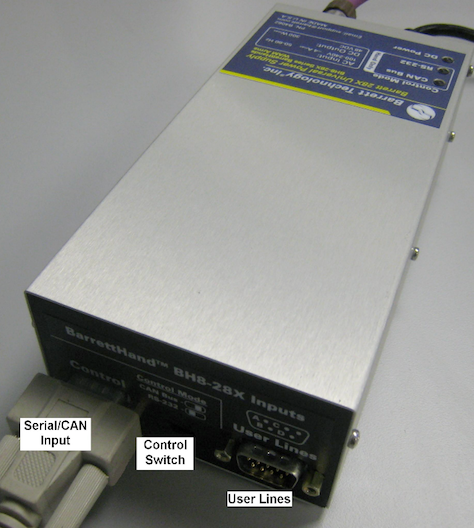

The BH8-28x power supply shown in Figure 2 is compact and designed to run a hand from a host computer over serial or CAN. The user should connect all wires which connect to the power supply before turning on power. A control switch sets RS-232 or CAN mode and accepts control input from the same DB9 connector. The unit is powered through an AC line cord and provides all the necessary power to the hand. Internally, an industrial grade power supply called the Synqor AcuQor provides a semi-regulated 48 V to power the hand.

CAUTION: Do not try to power previous hand models with this power supply because earlier models were limited to 24 V. Never provide RS-232 signals while in CAN mode because it can cause damage to the electronics.

Electrical Cables

All necessary electrical cables are included in the basic BH8-282 System. The required electrical connections are shown in Figure 2. An AC Line Cord connects the Power Supply to a wall source. A DB9 Extension Cable provides the communications connection from a host computer via RS-232 serial or CAN. A Hand Cable for the particular Power Supply and BarrettHand™ supply communications, logic power, and motor power. This cable is durable and flexible, allowing the BarrettHand™ to be used on any robot with minimal effect on robot performance. Use the included set of adhesive guide clips for cable management. Since the control electronics reside inside the BarrettHand™ itself, no other electrical cabling is required.

The typical connection to BH8-282 systems use a Peak USB to CAN adapter that connects to a DB-9 extension cable and the BH8-28x power supply, which is shown in Figure 3.

Lab Bench Stand

The bench mount stand for the BarrettHand™, shown in Figure 4, is ideal for off-arm development. The durable Aluminum stand comes complete with cable management clips and mounting features to hold your BarrettHand™ unit securely on any flat surface. Non-slip rubber feet keep the stand from sliding during testing and programming. A threaded locking ring for base mounting will secure the hand to the stand.

Control Software and Firmware

The BH8-SERIES System control software consists of:

- BarrettHand™ Control GUI application and API,

- Firmware (latest *.tek file), and

- Example and demo programs.

BarrettHand™ Control GUI

The BarrettHand™ Control GUI is a cross-platform compatible Windows/Linux application that allows control of the BarrettHand™ quickly and easily. The BarrettHand™ Control GUI can be used to demonstrate functionality, test Supervisory and RealTime control sequences, and how to save those sequences as ASCII text or even as cross-platform compatible C++ code along with a Makefile (literally with the click of a “Generate C++ Code” button). See the BarrettHand™ Control GUI Manual for more information on the using this application and the requirements.

C++ Function Library

The BarrettHand™ C++ Function Library is an API for programming the BarrettHand™ using the C++ language on a Windows or Linux PC without having to manage various communication and timing issues. The library contains a hand control class that has easy-to-use functions that permit the use of Supervisory and RealTime commands in software developed by the user. All of the functions are available when the library and its dependencies are linked to the program. Dependencies are usually installed by default so the user can focus on development. The C++ API includes HTML generated documentation that describes all of the classes, variables, and methods that users should use in detail and gives examples.

The API is written in C++ and is compiled for Linux and Windows. The library provides a class from which you instantiate one BHand object and use it for all communications. The library uses a multithreaded mechanism for sending commands, which allows both synchronous and asynchronous access to the low-level thread and ensures that all communications are executed with high priority. The low-level thread manages all input and output buffers and makes controlling the BarrettHand™ easy.

Firmware

The BarrettHand™ has firmware that resides on the control electronics inside the palm. The firmware is a compiler generated text file that may be uploaded to the hand through the boot loader and the configuration tab in the GUI. The firmware receives commands, controls the motors, sets and retrieves properties, and reads or writes to the EEPROM.

System Options

Arm Adapter

Barrett Technology provides an arm adapter (Figure 5) matching the make and model of any robot specified by the customer. This lightweight arm adapter is made to work with the end-effector bolt pattern on your robot, allowing quick, easy mounting and wire management for a BH8-SERIES System. The arm adapter is bolted to the end of the robot arm and the BarrettHand™ is secured to the arm adapter with its standard threaded locking ring. The arm adapter is also equipped with an anti-rotation feature to prevent rotation during operation.

Fingertip Torque Sensing Option

Barrett Technology offers a set of three factory-installed torque sensors (one per finger) for the BarrettHand™ system. Each sensor measures the torque externally applied about the distal joint over a range of +/- 1 N-m. This option uses strain-gages to measure the differential tension in the "tendon" running through each finger to the second joint. The information is processed in additional on-board circuitry when this option is installed, it is accessed by requesting the present strain-gage parameter. The strain-gage parameter represents the amount of strain on the strain-gage sensors (values can be calibrated by the customer to relate strain to joint torque).

Tactile Sensing Option

The BarrettHand™ with Tactile-Sensing provides 24 cells of tactile-array data per finger plus 24 cells for the palm. Note that the Perception Palm option replaces the palm's tactile array. The density of cells becomes higher towards the very tips of the fingers where finer spatial resolution is desirable. The entire Tactile-Sensing option is seamlessly integrated with the BarrettHand mechanically, electronically, and in the firmware and software. Furthermore, the calibration data is stored with each fingertip and the palm so that if you swap fingers, for example, the system is intelligent enough to maintain the correct calibrations.